Slurry Seal & Microsurfacing

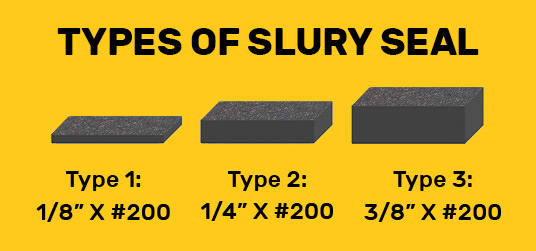

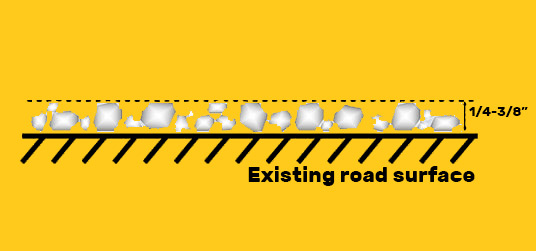

Slurry seal is a thick, cold mix paving surface treatment that provides a layer of protection to the asphalt. Think of it as industrial grade asphalt surfacing. It contains aggregates, asphalt emulsion, fines, polymers, and water for workability. This mixture is applied to the surface of the asphalt via a spreader box to create a level and even plane. The slurry seal services offered by our Ogden team are best used on roads or streets with heavier traffic, where enhanced durability will have the greatest effect. It typically takes between 8-10 hours to fully cure, depending upon the mix and the application. This allows for a quick return to traffic and minimal inconvenience.

Microsurfacing is very similar to slurry seal but has some slight differences. Consisting of asphalt emulsion, aggregate, water, chemical additives, and polymers, microsurfacing is an asphalt pavement surface treatment. It can be used to correct uneven areas and provide a durable and strong surface to the asphalt. Unlike slurry seal, microsurfacing does not rely on evaporation to harden. The chemical additives allow the asphalt emulsion to settle on its own. This means microsurfacing hardens faster than slurry seal, so it can be used on surfaces which can’t be shut down while the surface hardens. It also does not require direct sunlight, so it can be applied on shady streets or other areas which do not get much sun.

The slurry seal and pavement microsurfacing services provided by our Ogden team are excellent preservation methods for repairing minor cracks or moderately distressed asphalt. If you are not sure if your asphalt pavement needs to be resurfaced, contact Andersen Asphalt. We serve clients in the states of Wyoming, Utah, and Idaho. We are also proud to serve the communities of Salt Lake City, Logan, Layton, and Park City.

Client Testimonials

Business We've Worked With

Contact Us

We proudly serve the communities of Logan, Layton, and Park City.